Engineering and Construction

Our building process is the result of decades of refinement. Small tweaks and improvements have compounded over the years to yield canoes that are expertly designed, and hand built by paddlers for paddlers. We use only high quality materials and stiffen all of our hulls with Kevlar and carbon fiber reinforcements; never any foam.

years in the making

Design

Our canoes designs have been refined for decades with input from industry giants including Dave Curtis, David Yost, and Harold Deal. Each canoe design starts with pencil and paper plans which then become a cedar strip prototype canoe. The prototype is paddled, scrutinized, tweaked, and altered for incremental improvements. Each element of the design is considered and reconsidered until the design’s exact purpose is realized. Then, from the protype, a mold is built. The mold is the tool that is used to build consistently excellent canoes for our customers.

quality materials, time tested techniques

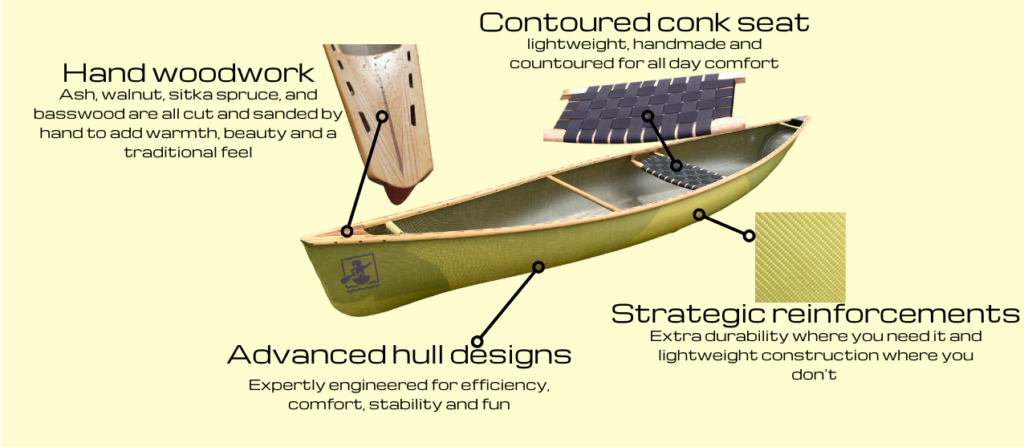

Each canoe is built inside of one of our high quality molds to ensure consistency. They are built from the outside-in, meaning that what becomes the outermost layer of the canoe is the first layer we put into the mold. We start by spraying the mold with a layer of color gel coat or clear coat, products that are much like the paint found on a car or truck. We then start adding layers of woven fiber cloth made of aerospace and military grade materials like Kevlar, carbon fiber and fiber glass. We permeate all the fibers with a vinyl ester resin system to tie everything together. All of our canoes are built with multiple full layers of woven fibers but then are also reinforced with more partial layers where they need to support extra strain or are most likely to require stiffness or durability. This system of partial reinforcements has been refined over decades and allows the boats to be robust where needed while saving weight when possible.

We offer our canoes made in several different combinations of materials called layups. Each layup is specifically designed to emphasize different priorities like affordability, weight savings, modern aesthetics or durability. Allowing customers to select their layup helps ensure that we deliver the perfect boat for their uses.

detail, comfort & function

Construction

Once the hull is completed and removed from the mold, the canoe is finished with wood trim and well considered accessories. Each detail not only adds a handsome flair to the canoe but also contributes comfort and function. The slotted gunwales save weight and allow water to efficiently drain from the canoe on the portage and during transport and storage. Webbed seats are offered in multiple configurations and with multiple contour options to ensure the paddlers can find all day comfort. Ash bow and stern handles make carries a breeze and add tie down points. We work with customers to make sure their options support their style and ensure a canoe that will fit the, like a glove all while making their paddling buddies jealous.